For the first release of the Wolverine Ditcher, Elmer’s has focused on improving design quality, maintenance and beefing up areas of potential failure. Here are the points that have been updated:

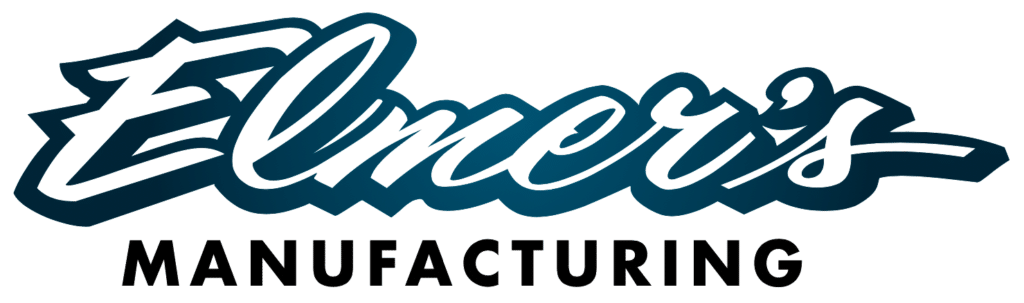

- Improved Chain Case Design – Upgrade Available

- Improved to a split case design to allow the bottom chain case (and all the chain oil) to remain intact for driveline maintenance.

- Better build design allowing for higher quality welds and overall strength improvements.

- Relocated Grease Zerk to external Position for easier maintenance and reduced contamination to chain case oil

- Improved to a split case design to allow the bottom chain case (and all the chain oil) to remain intact for driveline maintenance.

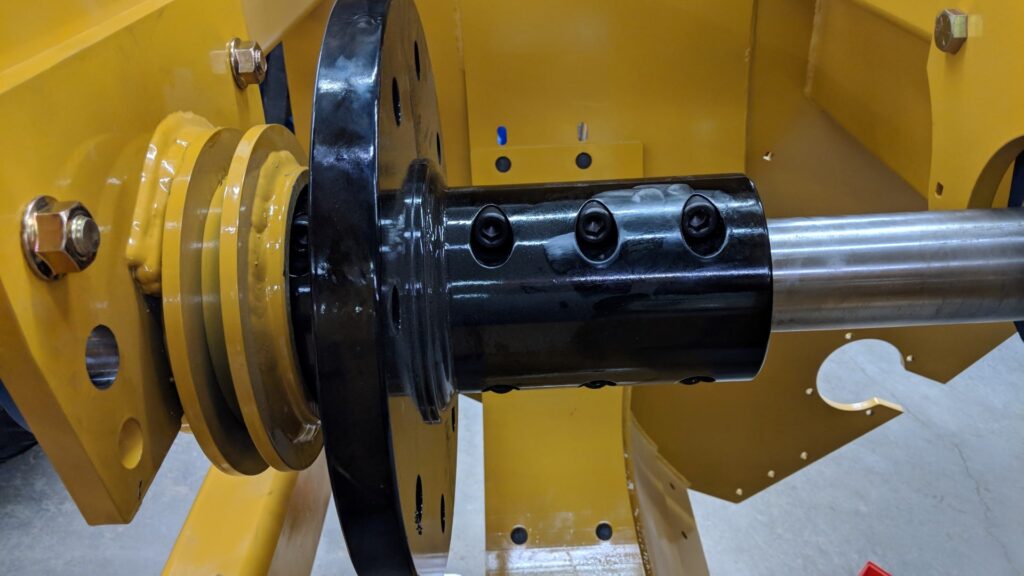

- Split Hub for Ditcher Fan – Able to retrofit, Ask for details

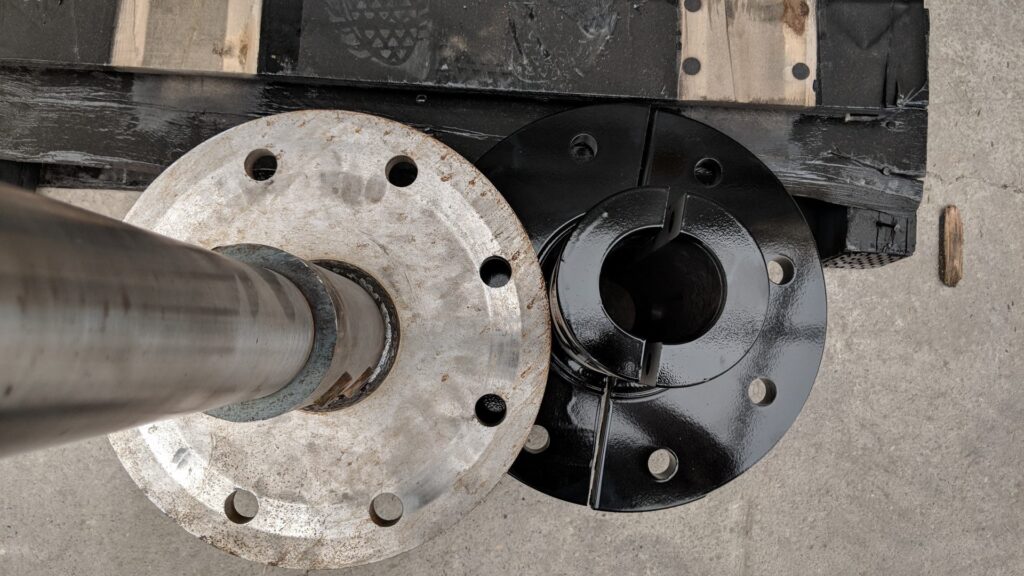

- Shear Bolt Break Away Fan Paddles – Able to retrofit, Ask for Details

- Changed from folding paddles, which still left a lip on the fan, to shear bolts allowing the panel to swing away for a more consistent action and quicker resetting in the event of contact with a large object.

- Shear bolt is a standard Grade 5 – ½ x 2 ¾ bolt available in most hardware stores.

- Easily Replaceable Hardened Bushings on Paddles to Protect Flywheel

- Changed from folding paddles, which still left a lip on the fan, to shear bolts allowing the panel to swing away for a more consistent action and quicker resetting in the event of contact with a large object.

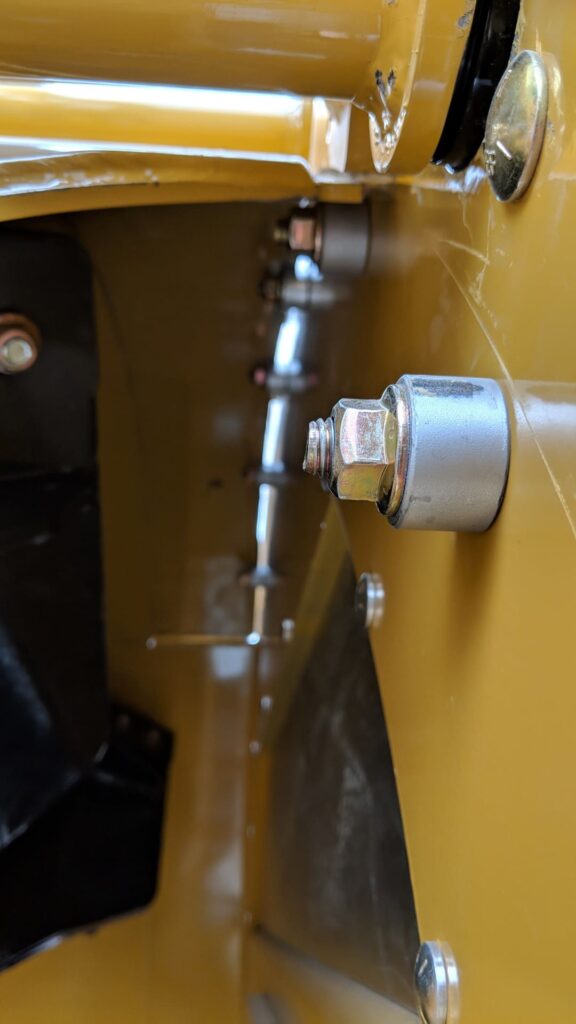

- Upgraded Chute Design – Not recommended for Retrofit

- Redesigned to improve performance for terracing or windrowing the dirt, long-term durability and easier serviceability

- Eliminated grease points on the chute with new larger and externally removable bushings

- Changed from one cylinder to dual cylinder for stronger and smoother operation.

- New gate guide reduces dirt build up resulting in smoother travel when changing directions.

- Chute Deflector on the left side to improve accuracy when moving dirt close to the machine.

- Redesigned to improve performance for terracing or windrowing the dirt, long-term durability and easier serviceability

- Added PTO Shaft Loops and Improved Shield Clamp – Upgrade Available

- Relocated vertical cutting edges from outside to inside. – Upgrade Available.

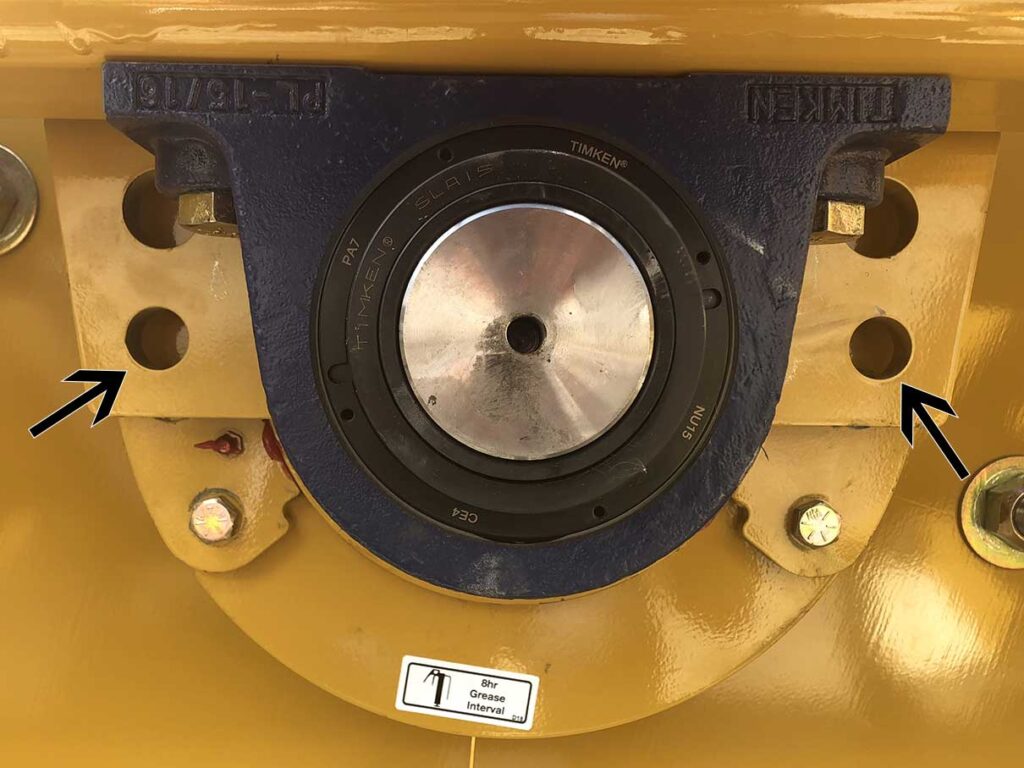

- Built-in Rear Bearing Puller

- Floatation Tires – Upgrade available

- Removed “The” and “Extreme” from the product name, adjusted and cleaned up logo.

Stay Updated

Recent Events & News

Jul 23, 2024

Haulmaster CONNECT 12.2.1 Change Log

The primary focus of this release has been to allow for future development and increase stability and connectivity. Please visit elmersmfg.com/connect for…

Jul 16, 2024

Elmer’s Manufacturing Announces Industries Largest Inline Tandem – Haulmaster 2500 Grain Cart

Largest Inline Tandem Grain Cart in the Industry The Haulmaster 2500 grain cart revolutionizes efficiency with its 2500-bushel capacity, allowing…

Jul 16, 2024

Elmer’s Manufacturing Announces All NEW Hive Motherbin

Harvest with Increased Volume and Efficiency Elmer’s grain carts have been pushing the status quo for on-field grain transport efficiency…