Innovation that simplifies your farming operation

Farming Equipment That’s

designed for rugged conditions, backed by world class support.

Elmer's is a farming equipment manufacturer in Altona, Canada, with the aim to make you more capable, productive and profitable. From our Parts Guy to our Lead Engineer, our mission is to produce the best farm equipment for the needs of the progressive farmer across the globe.

Technology to

Simplify and Modernize your harvest experience.

Elmer’s continues to expand its facilities and expertise to maintain the company’s objective of designing and manufacturing farming equipment that meets the needs of today's high tech farmer.

Elmer's Manufacturing

Who We Are

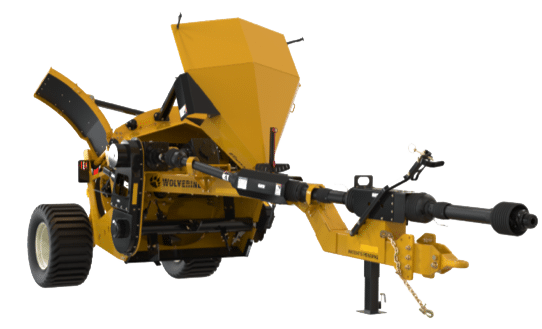

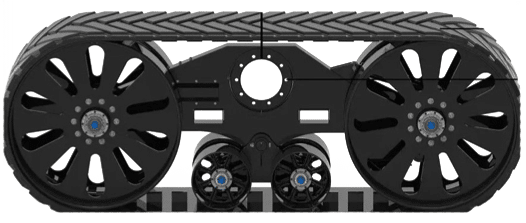

We have grown from a small farm business in 1978 to a farming equipment manufacturer that designs product lines for any size farming operation. Today that includes high capacity Haulmaster grain carts, the revolutionary Super 7 Harrow, the Wolverine Ditcher and the Ravage Bale Processor.

Stay Updated

Recent Events & News

Privacy Policy

2024 Haulmaster Updates